Well it wasn't long before snow fell. Wasn't a lot but covered the ground with a centimeter. Doesn't really matter as the jobs aren't complete anyway.

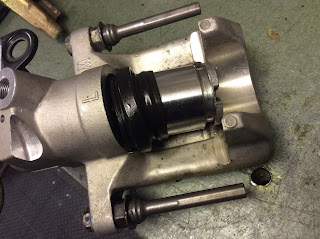

I got the new rear wheel bearing in place. The final part of the bearing I pressed in using the locking ring which I had put in place to know exactly how far to press. Once part of the ring slipped into the groove I knew it was far enough.

Removed the boot carpet and cover revealing the petrol tank and cover for diff, reversing light control box etc. It's been off and on so many times I should use riv nuts instead - I'll put it on the to-do list!

Then it was on to removing the drive shaft and half shafts. They all came off comparatively easy. Then it was a case of lifting out the diff but which way?

The offside half shaft removed (left hand drive)

I twisted it around and started to drop it out under the car between the chassis frame, not easy as it's pretty heavy. Use the motorcycle lift to gradually lower it. BUT hit a problem when I found out the diff was approx. 3mm too wide so got stuck in the frame! What to do? It wouldn't go out through the top because of hand brake cables, wires etc. not out of the side because of the rear suspension mount bolts were put in as advised, facing forward which meant they couldn't be removed because the tank was in the way! Then started emptying the tank of 20 litres of fuel (should have used it up before I took it off the road I hear you say!) but gave up as it's very time consuming to then remove the tank mounts, tank etc.

I then decided it was possible to grind the diff case very slightly where the case joined the rear diff cover without any damage to its integrity. Did several passes to only take away the minimum required (see arrow)

Lowered nice and gently on the MC lift.

Comparison check between original on the left and the LSD. I had an idea it was a medium case but gambled it was small when comparing photos from the ebay advert.

Looks good

Ground down approx. 3mm from the new case, hopefully it's enough to get it through the frame!

Wire brushed all the flaking paint away and then painted with rust remover.

Aluminium and black engine paint plus replaced gasket, drain and fill plugs and seals as well as sensor seal and retaining ring. Then torqued up the bolts. Also swapped the diff sensor with the new one I bought a couple of years ago.

Looks nice and clean. Next step is to refill with LSD diff oil and get it back into position in the car ....

... To be on the safe side and recommended by the BMW parts department I bought a tube of Loctite 5970, opened the case again and put it on both parts of the diff with the gasket in between. Then tightened to 70nm which wasn't mentioned in the workshop manual but I decided it should probably be around that. Tightened up the drain plug to 70nm, layed the diff flat on the bench and filled with approx. 1.1 litres of Limited Slip oil 75W-140

Swedish price about £25 a litre.

Just up to the filler.

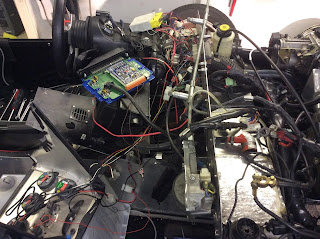

As a matter of interest and while I could get to the fuel pump connector I tested the engine compression.

Directly after I rebuilt the engine:

Compression after running engine was:

Cylinder 1 = 16 bar (232 PSI)

Cylinder 2 = 15 bar (217)

Cylinder 3 = 16 bar (232)

Cylinder 4 = 15 bar (217)

After 3000km it looks like this:

Compression with warm engine:

Cylinder 1 = 16 bar (232 PSI)

Cylinder 2 = 16.2 bar (235)

Cylinder 3 = 16 bar (232)

Cylinder 4 = 16 bar (232)

So I would say it looks very good.