I found out it was quite usual to have a micro leak or so in old modified sumps, I shall try some metal putty to see if that fixes it. The thought of changing the sump didn’t fill me with enthusiasm at all.

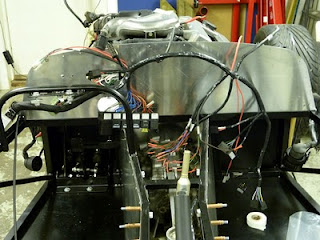

I started checking the BMW cable colours and ended up using a pair of magnifying glasses. The coloured strip on most of the wires is thinner than necessary! I have to buy the double crimp type cable terminators as the single ones are not at all recommended in Sweden, I’m not sure about the UK. As I mentioned the GKD cabling is marked very well so it’s just a matter of matching the colours plus the help from the guys on the GKD forum is invaluable.

I’m trying to finish odd jobs so I placed the petrol tank back in position and was wondering whether there should be rubber in between the tank and support brackets to stop vibration. I’m waiting for the second fuel sensor to arrive as well as the large aluminium washers to keep the senders in place. Fuel pipes are in place and cable tied as well as the front and rear wiring looms.

I can’t cut the hole for the exhaust pipes in the side aluminium panel as I haven’t got the gaskets for the manifold; should arrive tomorrow; don’t want to cut in the wrong place. Hopefully also the brake pipes will be ready to pick up tomorrow as well so I can get them installed. Lower steering arm photos are still at the IVA inspectors, hopefully they will be accepted. The track rod arm challenge is with Peter so hopefully he will come up with a solution soon.

I really dislike having so many jobs half finished.

Welcome to my never ending GKD Legend build. The car became road legal in September 2011. The Swedish summers are fantastic but to survive the dark winters I always have a long list of improvements to do. The 1900cc 4 cylinder engine comes from a RHD 1998 BMW 318is M44. It has been upgraded many times over the years with eg. Mini Cooper S Eaton M45 Super Charger taking it from 140 to 220HP. (Parts list Jan 2020)

Sunday 20 March 2011

Saturday 19 March 2011

Not a good Saturday.

Started off today with quite a bit of enthusiasm, got the rear panel bent into shape. I first drilled the holes for the bottom edge of the panel and then inserted cleco fasteners to keep it in place. I placed a few clamps on the top edge and then gradually put my weight evenly on the side edge of the panel and kept pushing little by little removing and reapplying the pressure. Once bent, a few more clamps kept the sides in place. I'm not going to attempt to bend the top edge yet, not sure if I'll get the panel off again.

The new panel has the hole for the petrol filler already cut out - nice!

Then I started laying out the main wiring loom and tried to work out what everything was and where it went. The wiring is extremely well marked. The problem came when I noticed the bulkhead panel had the holes for the fuse connector, relays etc on the same side as the steering wheel. The RHD version has them on opposite sides. I'm just waiting for confirmation from Peter that they should be on the passenger side.

I believe the holes just above the row of relays should be on the right, the passenger side!

Another worry is the small leak I noticed coming from the shortened sump. It looks like the weld and definately not the drain plug. I've got the feeling it's going to have to be changed, hopefully I can leave the engine in but it will still mean removing the gearbox. Happy days!

Took about 10 or so hours to leak this much.

Hopefully tomorrow will be a better day!

Tuesday 15 March 2011

Had the first Test today

A guy from the SFRO (IVA) came around to the house tonight and did the first test. In Sweden UK

- All the brake pipes must have the connectors changed to the "pressed" on type and also be surrounded by a clear plastic tube for shielding.

- no comment, apart from the clear plastic will keep them looking newer, longer I suppose!

- The fabricated lower steering shaft must not contain welds.

- Maybe I can get one made up.

- Track rod end must not contain welds. Swedes are a bit strict on welded joints but apparently they have had one or two accidents with welds giving way!

- Perhaps I can buy one the same length without the weld.

- Cannot use a 4 point safety belts!

- Bit daft this one, I just have to disconnect one of the shoulder straps from the anchor point! 4 point encourages street racing

- A comment: The total weight of the vehicle + fuel + driver (70kg) plus 50kg (extra!) must exceed 6.666 Kg per kW(103) = 686kg.

- I have no idea at this stage but I'll add something heavy if needed!

- Sound level must be under 84dB - no idea at this stage what it's going to be. Told there was an I-Pod app to measure this.

Apart from that everything was fine, I can use my sports steering wheel with boss connector, long extrusions like switches etc. are totally okay for the dashboard etc.

VIN number punched into the chassis

Overall I'm a little disappointed as it would have been okay in a UK

Saturday 12 March 2011

Running up to the first IVA

I contacted the Swedish equivalent of the IVA (SFRO) and a guy can drop around almost anytime. I don’t want to do too much before the first test so I’m just doing odds and ends. Bolted the engine and gearbox mounts including attaching the earth strap. I still have to torque the gearbox bolts to the engine.

I was abit worried about a belt adjuster not fitting because of the chassis but then I realised it was the air conditioning belt tensioner so didn't need it anyway! There seems to be plenty of room infront of the engine, perhaps there will be space for shopping bags!

Fitting hoses next.

I thought I better check the fitting of the exhaust manifold and it fits really well. Hopefully it will be fairly easy to cut a hole in the side paneling for the pipes to go through.

I need to buy manifold gaskets and new bolts.

Next I fixed the gearstick bracket and the handbrake bracket, both fairly simple but a task to tick off the list at least.

The gearstick is now tightly in place, it'll look good with the new covering I bought!

Handbrake attached, just need the cables attached to the rear calipers.

On to the back and attached the fuel tank brackets temporarily. I had to modify the bends slightly at each end as they didn't sit parallel with the chassis. The manual is a little vague about the brackets so I'll leave them attached by only the front bolts.

The tank strap is the one in the centre. The tank is raised and put in place from underneath and then a strap put in place at each side to stop it falling back.

Thursday 10 March 2011

Engine in!

Made some good progress this week, added the twin roll bar, sorted out the sump and put the engine and gearbox in. The roll bar was pretty straight forward as it fitted very well and it looks great!

6 bolts on either side and job done!

Next job was to change the sump to a shorter version. I forgot that my engine is actually the M44 version of the BMW 318is model as it is very similar to the M42.

The car is very low to the ground so a normal sump would bottom out, a shorter sump solves the problem.

The sump I got from Peter was for the M42 and I realised something was amiss when I removed the old gasket. The sump has a recess for the rubber gasket whereas the M42 sump is flat and takes a cork(?) type gasket. More consultation with Richard and it was a matter of just changing to the new M42 sump and using a flat M42 gasket.

Once that was solved I then realized the M42 sump was pre 1995 which meant the bolts required to hold it to the engine block were 18mm instead of 30mm. I ended up buying 18 new shorter bolts as I didn’t fancy shortening all the old ones!

Then there was the dipstick guide that was obviously too long, I used a plumbers pipe cutter to shorten it by about 2 cm .

While the engine was on the stand I took the opportunity to clean it as well as change plugs and oil filter.

The filter is the type without a nut so it has to be gripped and turned. I ended up buying a great little tool from my favourite store "Jula"

Neil came round tonight and we spent two hours bolting back the gearbox and after a bit of giggery pokery managed to manipulate both gearbox and engine into the tiny engine space and onto the rubber supports. Looking closely at the mass of components on the left side of the engine I just hope there is room for the steering shaft etc. All in all I’m very happy so far!

Had to remove the rubber mounts on one side plus the mount housing on the passenger side just to get the engine to slip into place.

Very happy indeed but what challenges lurk around the next corner!

Sunday 6 March 2011

On to the engine

I bought an engine lift and stand yesterday from a place called "Jula" a large chain of hardware stores selling everything especially great and fairly cheap automotive tools. Even if a tool is used only once it's worth buying, that's my policy. One can always put it on e-bay (blocket.se) if space becomes an issue.

The engine is very front heavy so the balance bar comes in handy.

The engine stand didn't fit because of the clutch assembly stuck out. At first I thought I'd have to take off the clutch and flywheel but with the help of Richard from the GKD forum I managed to solve it. Bought a length of hardened 12M bar, chopped it into four lengths and then used washers and nuts to keep it nicely in place against the engine and stand. I was a little reluctant at first to let the stand take the whole weight of the engine but it worked fine.

I couldn't bolt it to the sump as that's what I need to take off and swap with a shortened version. It's fairly central, good enough to enable the engine to revolve.

Engine nicely on the stand and fairly easy to revolve it. I got a floor covered in water once the water drained out!

Oh and I fixed the front caliper thread problem, I ended up buying a M12 1,5 tap and re did the thread, perhaps some sand got in there when I sand blasted it. Car is now on the ground supported by all four wheels and nothing has dropped off - yet!

Not that I have adjusted anything yet but I seem to have quite a bit of Toe out and the track rods are wound just about all the way in. Alice is the first passenger!

Thursday 3 March 2011

Harsh braking

All brakes are just about finished, I have an issue with the drivers side front caliper bracket as it doesn't seem to be a standard thread. Other than that I have laid out all the brake pipes and connected the pedal box and both brake cylinders and clutch.

The cylinders come with rubber rings that can be discarded. The size does matter!

This kit is a left hand drive so most things have to be mirrored accept of course the pedals! When the pedal box goes in it has to be bolted to the floor pan, don't forget to use some sealant round the holes!

The 3 way brake connector bolted to the rear diff plate.

I'm running out of things to do before the engine and gearbox go in. I cleaned the gearbox which now looks pretty good, not sure whether to change the clutch or not, will take a look in the next day or so. I wanted to put the wheels on before I try and get the engine in as I need to roll the car back to give room for the lift.

Nice rear end!

Once I sort out the front caliper bracket problem I'll connect the brake hoses and get the wheels on.

I'm really happy with the wheels, after taking them to one of those DIY jet washers they look great. I even ordered 4 new BMW centre covers from e-bay to really give that final touch!

The gearbox just needed a quick squirt of WD-40 and a wire brush but the engine requires a little more. A final clean may have to wait until I can take the engine somewhere to have it professionally cleaned but that will have to wait until I have it fitted in the car!

Subscribe to:

Posts (Atom)